- Home Page

- Company Profile

-

Our Products

- Magnetic Separators

- Single Drum Magnetic Separator

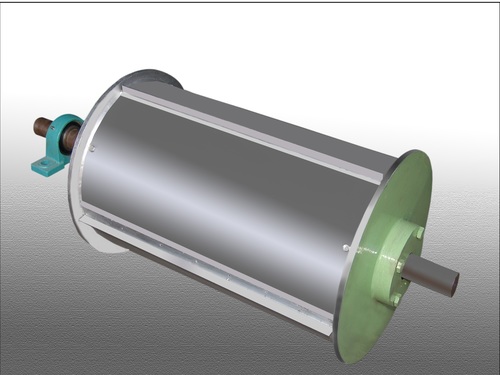

- Drum Type Magnetic Separator

- Coolant Separator

- Wet Drum Magnetic Separator

- Inline Magnetic Separator

- Double Drum Magnetic Separator

- Pipe Line Magnetic Separator

- Low Intensity Magnetic Separator

- Magnetic Drum Separator

- Magnetic Roller Separator

- Overband Magnetic Separator

- Magnetic Equipments

- Permanent Magnetic Equipment

- Vibrating Equipment

- Industrial Magnetic Pulley

- Vibrating Screen Machine

- Magnetic Lifter

- Electromagnetic Vibrator

- Gyro Sifter

- Magnetic Separators

- Extra Links

- Contact Us

Showroom

Use our Magnetic Separators which are used in several industries for various purposes. They are featured by compact design, energy efficient, low maintenance, highly durable, excellent performance, etc. They can be availed from us at reasonable prices.

We deal in wide range of Magnetic Equipments which are featured by reliability and durability, longer machine's operational life, excellent performance, etc. They are used in many industries in various equipments.

Use our high grade quality Permanent Magnetic Equipment which are used in several industries in different equipments such as magnets, magnetic equipment, etc. They give seamless performance, have long service life and have effective separation property.

We provide Vibrating Equipments which require less maintenance, give noiseless processing and impeccable performance. They are suited for diverse industrial sectors, and are available in different types, designs, shapes, etc.

We deal in wide range of Industrial Pulleys which are available in different designs, sizes, etc. They are featured by rugged design, superior surface finish, rust proof, accurate dimension, etc. The offered products are used in conveyor machine, shipping, marines, etc.

We deal in wide range of Vibrating Screens which are available for clients in different technical specifications. The provided screens are suitable for carrying various kinds of materials to remove out the specific materials before blending, packaging or batching.

Use our Magnetic Lifters which are very much suitable in industries such as foundry, plastic and scraps dealing. They are well appreciated in the market for their features like robust construction and less power consumption.

Use our high grade quality Electromagnetic Vibrators which are high efficiency, robust construction and impeccable performance. They are used in industries for different purposes, and are manufacture in line with industry standards and norms.

Because of their versatility and ease of use, these Gyro Sifters are a vital instrument for process optimization and quality control. They are available in a range of sizes and combinations to suit varying material properties and throughput needs.